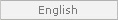

Raw material will be fed into jaw crusher evenly by vibrating feeder, while the dust and small granules will be seperated by the grizzly bar of feeder and carried out by belt conveyors. Processed material of jaw crusher will be transported to the cone crusher via belt conveyor. After the secondary crushing, material will be seperated by vibrating screen according to the size to go to the sand making machine or to back to cone crusher for re-crushing. Being re-shaped by the sand making machine, the final products will be seperated by vibrating screen into different piles according to customer’s requirements.

|

|

Vibrating feeder |

Jar crusher |

Cone crusher |

Vibrating screen |

Vertical shaft impact crusher |

Vibrating screen |

1#belt conveyor |

2#belt conveyor |

|

Plant1 |

GZD960X3800 |

PE600X900 |

CSB75 |

2YZS1848 |

VSI5X8522 |

3YZS1860 |

B500X10m |

B800X19m |

|

Plant1 |

GZD1100X4200 |

PE750X1060 |

CSB160 |

2YZS1860 |

VSI5X9532 |

3YZS2160 |

B500X10m |

B1000X21m |

|

Plant1 |

GZD1300X4900 |

PE900X1200 |

CSB240 |

2YZS2160 |

VSI5X1145 |

3YZS2460 |

B500X10m |

B1200X24m |

|

|

3#belt conveyor |

4#belt conveyor |

5#belt conveyor |

6#belt conveyor |

7#belt conveyor |

8#belt conveyor |

9#belt conveyor |

10#belt conveyor |

Capacity |

|

Plant1 |

B800X21m |

B500X22m |

B800X18m |

B800X24m |

B500X15m |

B500X15m |

B500X15m |

B500X15m |

80-120t/h |

|

Plant2 |

B1000X21m |

B650X22m |

B1000X19m |

B1000X24m |

B650X15m |

B650X15m |

B650X15m |

B650X15m |

150-200 t/h |

|

Plant3 |

B1200X21m |

B650X22m |

B1200X20m |

B1200X24m |

B800X18m |

B800X18m |

B800X18m |

B800X18m |

250-300 t/h |